At its factory in Ystrad Mynach, near to the site of the former Penallta Colliery, staff at the world’s biggest producer of crackers and wrapping paper are gearing up for anything but a quiet Christmas.

Amid the whirring, buzzing and beeping of the towering printing machines at The Design Group’s warehouse, a workforce of around 400 are busy finalising late orders from UK retailers.

The Design Group prints around 425 million metres of wrapping paper per year locally, which equates to over 1 billion feet and is enough to reach the moon.

Supplying a whole host of clients – from Aldi and Home Bargains to John Lewis and Kurt Geiger in the UK, and Costco, Walmart, and IKEA globally – design and manufacturing staff share the Ystrad Mynach site and work 14 months in advance, meaning next year has already been put to bed with designs already being drawn up for 2019.

Its output ratio is roughly split into an 85% Christmas focus and 15% on “everyday” items for the likes of Easter, Valentine’s Day, and Mother’s Day.

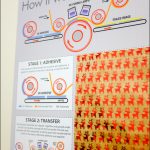

Finalised designs are embedded onto a polymer roll in one of 24 printers which can print at a maximum speed of 650 metres a minute.

Ink is then layered and printed onto paper from reels more than a metre thick, before being dried, shaped, and rolled back together.

Factory manager, Andrew Chivers, 44, has worked for the group for 20 years and hailed the move to water-based ink colours.

He said: “We had an £8 million pound investment in two new printing presses in 2013 to move to water-based printing, which allow better efficiency and eco-friendliness.

“It also means we can add holograms, foils and glosses, and have a high-speed metalliser for the shiny designs.

“We have 14 base colours, which include three varnishes, and they’re now all recyclable and food-packaging approved. We currently have recipes for over 7,000 colours, which are developed both in-house and can be ordered by clients.”

The paper is then fed into one of 16 convertor machines, which crops and cuts 250,000 metres of wrapping paper per 12 hours.

Machines are in production 24 hours of every day of the year, bar the two weeks when the factory closes over the festive period. Around 65 million retail wrapping paper rolls are produced annually.

The company’s investment also saw production moved from two factories onto the one site in Ystrad Mynach, which was visited by the Queen and Duke of Edinburgh in April 2014.

The group’s upmarket Tom Smith brand was granted a Royal Warrant in 1906 for the supply of Christmas crackers, and it currently holds the honour of producing wrapping paper and crackers for Buckingham Palace. Tom Smith accounts for five percent of output, with 95% under the Design Group’s own brand.

Thousands of designs come from the latest trends, whether that be colour schemes, fashion, culture, or advertising. A few years ago, department store John Lewis’ use of animals in their advertising campaigns contributed to a national trend.

When global clients – 35% of total production is exported worldwide – visit the site, they get a full tour of both manufacturing and design facilities, including the ‘trend room’, where designers have collated themes.

One worker, who did not want to be named, said: “Last year, Disney’s Frozen was high in demand, and there was a constant requirement for reprints to keep up with demand. People were literally fighting over rolls of Frozen wrapping paper.

“But here, it’s like Christmas every day.”